One-chamber three-point spreader

The uncomplicated all-rounder

D 301 | D 601One-chamber three-point spreader: the uncomplicated all-rounder

Unbeatable durability

innovative material combination stainless steel + plastic, maximum corrosion protection

Cost-effectiveness

exact dosing accuracy

low oil consumption and low pressure and power requirement through highly efficient hydraulic block

High payload and driving safety

compact attachment to carrier vehicle

center of gravity close to vehicle and low net weight

Innovation that matters

patented and proven spreading disc

homogeneous spread pattern

exact lateral distribution of spreading material

maximum spreading capacity

Screw conveying

exact dosing accuracy through proven design and durable construction leads to maximum spreading capacity

suitable for different spreading materials thanks to optional agitator shaft (does not require an additional hydraulic unit)

Simplicity

manual operation possible, intuitive handling also without control unit

Sophisticated detail solutions

easily collapsible stand leg provides a safe platform

simple and intuitive handling of tarpaulin cover

Many equipment options

intuitive control

splash guard

reversal of screw movement

flasher or rotating beacon

PTO pump

agitator shaft

warning sign

"A real milestone in the three-point spreader segment"

The innovative material combination of stainless steel and plastic combined with proven kugelmann technology and ingenious details are the basis for our new three-point spreader generation.

Once more, we have turned everything upside down, questioned every stage of development and have gone our own way.

The basis, i.e. the complete base including the technical inner workings, is produced of stainless steel. The high-quality plastic tank is made by rotational moulding. Thus, we manage to produce a highly economic spreader with a very long service life.

The low net weight means low fuel consumption and the possibility of maximum load.

The configuration of a simple basis machine up to a spreader fully equipped according to your requirements and needs - everything is possible thanks to the thought-out modular design.

Detail solutions such as the specifically developed highly efficient hydraulic block complete the machine and make it a real milestone.

Junior manager Sebastian Kugelmann

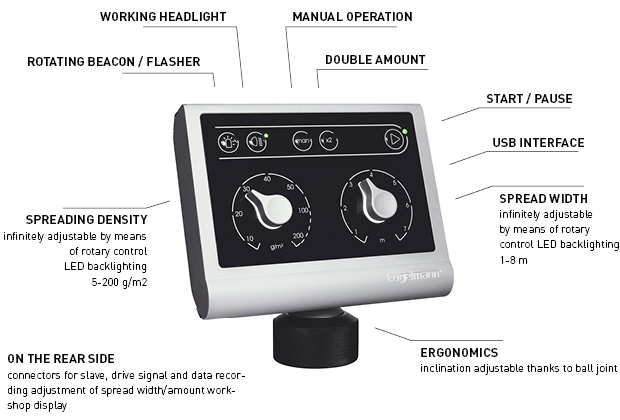

K-BASIC 2

With the K-BASIC 2, kugelmann has managed to launch a control system reduced to the most essential. As an interface between operator and machine, the control system combines intuitive operation and precise spreading technology. Despite the high tech solution with intelligent feedback and control function, the K-BASIC 2 is easily understandable and its use quickly becomes routine. You have everything under control without compromising on your work. The control system works entirely path-dependent. This means an economical and efficient use of spreading material.

A unique feature of our spreaders is the infinitely adjustable spreading width/density.

Gallery

download

............................................................................................................................................................................................

Brochure

Brochure

kugelmann D301 | D601

Download

PDF

............................................................................................................................................................................................

Operating Instructions

Operating Instructions (EN)

kugelmann D301 | D601

Download

PDF

............................................................................................................................................................................................

Spare parts list

Spare parts list

kugelmann D301 | D601

Download

PDF